Thermoelectric generator (TEG) is a zero-emission device that converts thermal energy into electricity based on Seebeck effect. Current thermoelectric matrials only exhibit excellent performance in a narrow temperature range, but the temperature difference across TEG should be as large as possible to improve its performance. So the segmented TEG (STEG) is believed to improve the performance effectively. Therefore, a calcluation method is proposed to optimize the length ratio of STEG, which increases the output power and efficiency as much as possible. Meanwhile, the power and efficiency factors used in this method are the development of traditionally used power factor and figure of merit. These two new factors directly reflect the relationship between thermoelectric materials and output power and convesion efficiency of TEG. We corrected the errors of the boundary conditions in the precious 3D model of thermoelectric module and proposed the new power factor and efficiency factor to evaluate the thermoelectric module. Additionally, we investigated the effects of the driving condition of vehicle, design of exhaust pipes and design of thermoelectric module on the recovery performance of waste heat through coupling the thermoelectric module with internal combustion engine.

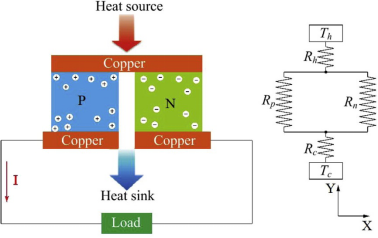

Figure 1. Schematic of thermoelectric generator (TEG)

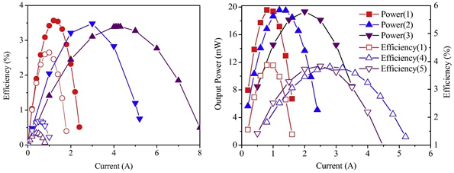

Figure 2. Power and efficiency of thermoelectric generator (TEG)

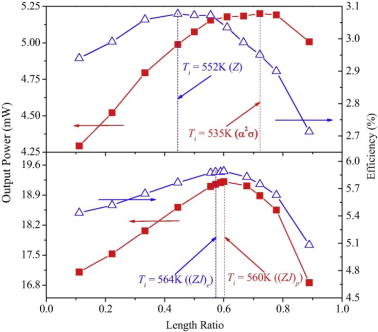

Figure 3. Power and efficiency of STEG at different length ratios

Address:Building 34, Tianjin University, Jinnan District, Tianjin

E-mail:kjiao@tju.edu.cn

WeChat

WeChat